When it comes to construction and engineering, understanding the materials you use is essential. Two terms that often come up are “reobar” and “reobars.” While they may sound similar, they refer to different components that can significantly impact the durability and strength of a structure. In this article, we will explore the differences, uses, and selection criteria for reobar and reobars to help you make an informed decision for your next project.

Understanding Reobar and Reobars

To truly grasp the differences between reobar and reobars, it’s crucial to define each term clearly. Let’s break it down further.

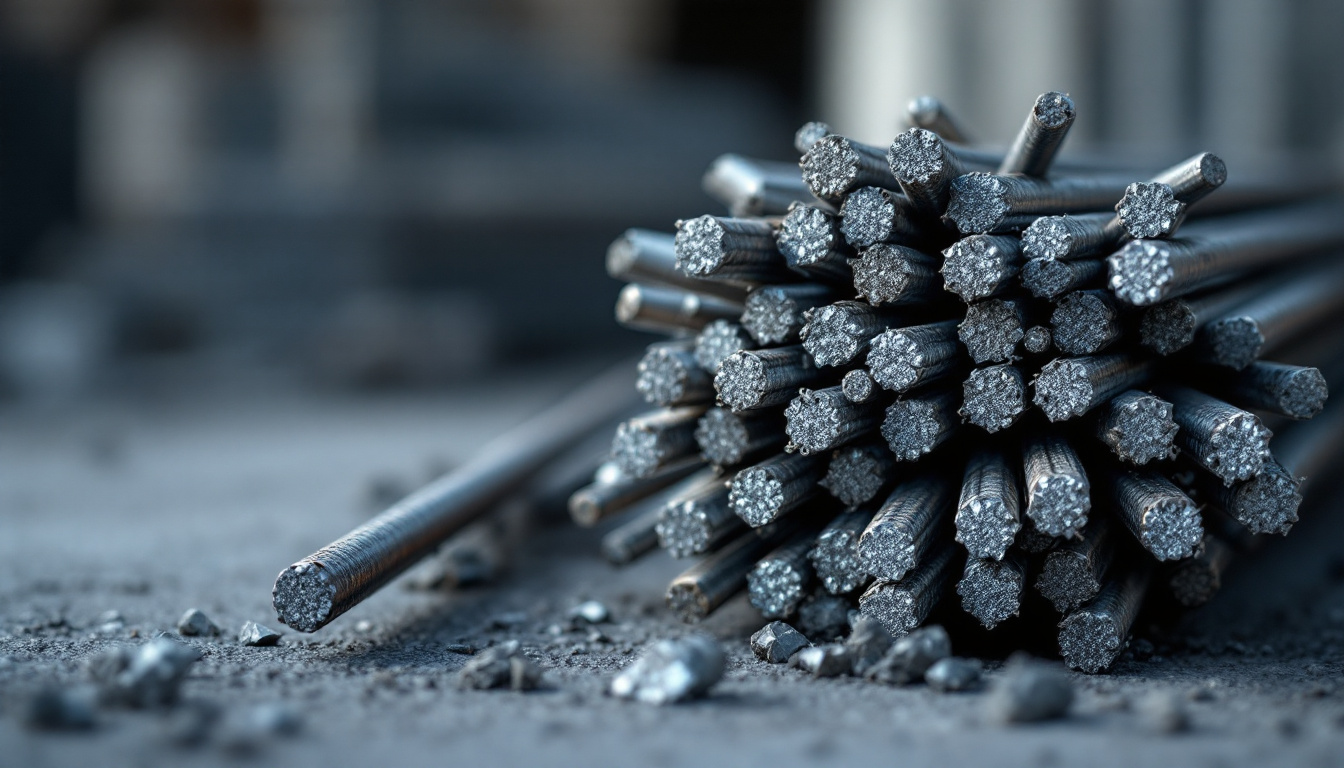

Reobars are a term commonly used to refer to a specific type of reinforcing steel bar that is critical in construction. These bars are usually made of carbon steel and have ridges along their surface to improve bonding with concrete. The primary purpose of reobar is to enhance the tensile strength of concrete, which is typically strong in compression but weak in tension.

Defining Reobar

Available in various sizes and grades, reobar is often used in slabs, beams, and foundations to ensure structural integrity. The standardized sizes and types allow engineers to select the appropriate reobar for specific projects, making it a fundamental component in modern construction. The manufacturing process of reobar involves hot rolling, which gives the bars their characteristic surface texture, enhancing their grip within the concrete. This mechanical interlock is vital for the longevity and durability of structures, particularly in environments subject to heavy loads or seismic activity.

Defining Reobars

On the other hand, reobars (often used interchangeably with reobar but more accurately referred to in the plural form) denote multiple pieces of reinforcing bars. It’s important to remember that while “reobar” refers to a single bar, “reobars” collectively describes an assortment of these bars used in a particular construction scenario.

Reobars come in various configurations and can be combined to support different structural applications. Understanding that reobars can consist of different grades and structural forms helps in planning the materials needed for a project. Essentially, they play the same role as reobar but in a greater quantity or variety. In large-scale construction projects, the use of reobars allows for the creation of complex frameworks that can withstand various forces, including tension, compression, and shear. Additionally, the strategic placement of reobars can significantly influence the overall performance of a structure, making it imperative for engineers to carefully calculate the required quantities and arrangements based on the specific demands of the project at hand.

Key Differences Between Reobar and Reobars

Having defined both terms, let’s delve into their key differences. Understanding these variances is vital when selecting the right materials for building projects.

Material Composition

Both reobar and reobars are predominantly made of steel; however, their material composition may vary based on specific structural requirements. While standard reobar is often a carbon steel alloy, some types of reobars may include additional elements such as chromium or nickel to enhance performance under specific conditions. Learn more about carbon on https://ugc.berkeley.edu/background-content/carbon-cycle/

This variation can influence the overall strength and corrosion resistance of the bars, which is crucial for longevity in construction projects, especially in areas prone to extreme weather conditions or moisture.

Structural Strength

Another significant difference lies in the structural strength. Reobar is often rated by its capacity to withstand tensile and compressive loads based on its diameter and the steel grade. When discussing reobars, one must also consider the total aggregate strength that comes from combining multiple bars. The arrangement and placement of reobars can significantly enhance the overall structural performance more effectively than using single reobar alone.

In projects requiring extensive load-bearing capacity, the use of reobars is critical, as it allows for a customized approach depending on the force demands and architectural design.

Cost and Availability

Cost is an essential factor when choosing between reobar and reobars. Generally, the price of reobar can vary based on size and quality, while reobars, being a collection of multiple reobar pieces, may offer economies of scale depending on how they are purchased and the bulk discounts available.

Availability can also be a concern. Simpler and more common types of reobar tend to be readily available at retail outlets and suppliers, while specific configurations of reobars may require special ordering. It’s a good practice to check local suppliers for the availability of both options before making any purchasing decisions.

Choosing Between Reobar and Reobars

Choosing between reobar and reobars can feel overwhelming, but with a little guidance, you can make a decision that suits your project’s needs effectively.

Assessing Your Project Needs

The first step in selecting the right option is accurately assessing your project’s requirements. Consider factors such as the type of structure, load-bearing needs, and environmental conditions. For example, a residential project may only require basic reobar, while a skyscraper would benefit from a more comprehensive arrangement of reobars.

Understanding your specific requirements sets the foundation for determining whether you need single reobar pieces or multiple reobars grouped together.

Evaluating Durability and Longevity

When assessing durability, consider the environment in which the structure will exist. If the project is near saltwater or in an area with high moisture levels, you may want to choose reobars made with corrosion-resistant materials. The emphasis should always be on long-term performance and maintaining the integrity of the structure over time. Click here to find more about resistant.

Considering Environmental Impact

Sustainability is becoming increasingly important in construction. Selecting the right materials can lower the environmental footprint of your project. Rebar and reobars made from recycled materials or those that require less energy for production can be favorable choices.

By evaluating the environmental impact of your materials, you not only contribute to a healthier planet but can also improve the marketability of your completed project.

Common Misconceptions About Reobar and Reobars

With two terms that are so closely related, misconceptions can arise. Let’s take some time to clarify these misunderstandings.

Debunking Myths About Reobar

One common myth is that reobar is only used in large-scale construction. In reality, reobar is also essential in smaller projects, such as residential homes or renovations. Its strength-to-weight ratio makes it adaptable for various applications.

Another misconception is that all reobars are created equal. In truth, reobars come in different grades and forms, each tailored to meet specific construction requirements. Not recognizing this can lead to insufficient strength for particular applications, jeopardizing safety.

Clearing Up Confusion About Reobars

Many confuse reobars with other types of reinforcement materials when, in fact, reobars are distinct in their ribbed design and steel composition. Their design enhances mechanical bonding with concrete, a characteristic specific to reobars. Understanding this feature is critical for any construction-based decision.

Additionally, there might be confusion regarding compliance and standards. While reobar and reobars meet different regulations in different regions, doing thorough research can ensure your selection adheres to local codes.

Making the Most of Your Selection

Once you’ve determined the right choice for your building project, implementing best practices can maximize the effectiveness of your material.

Best Practices for Using Reobar

Proper installation is key to achieving the desired results. Ensure reobar is placed according to engineering specifications, maintaining the correct spacing and alignment. Adequate concrete cover is also essential to increase durability and reduce corrosion risk.

It’s also invaluable to routinely check materials before use. Verifying the quantity and quality of reobar before commencement can save time and resources during the construction process.

Tips for Maximizing Reobars Efficiency

When working with reobars, organizing the quantities and types before the project begins can streamline the construction process. Having a clear plan and proper labeling can minimize confusion and errors.

Additionally, involving experienced professionals during the planning and installation phases can ensure that your selection of reobars is utilized effectively, enhancing the overall outcome of your project.

In conclusion, understanding the differences between reobar and reobars is crucial for anyone involved in construction. By assessing your project needs, evaluating durability, and addressing common misconceptions, you can make an informed decision that ensures the strength and longevity of your structure.

Other resources: Safety Strip Essential Protection for Your Construction Site’s Work Areas